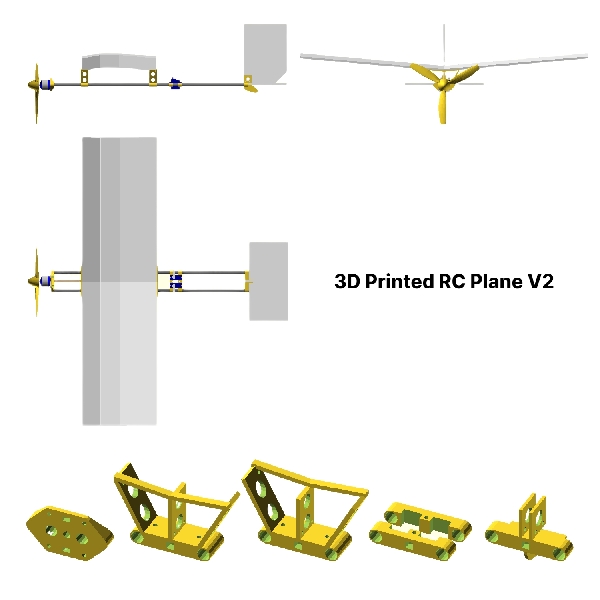

3D Printed RC Planes

Next steps

- Get more flight practice with the current single tube design

- Build up the V2 plane in parallel, modifying the design as print or assembly issues arise

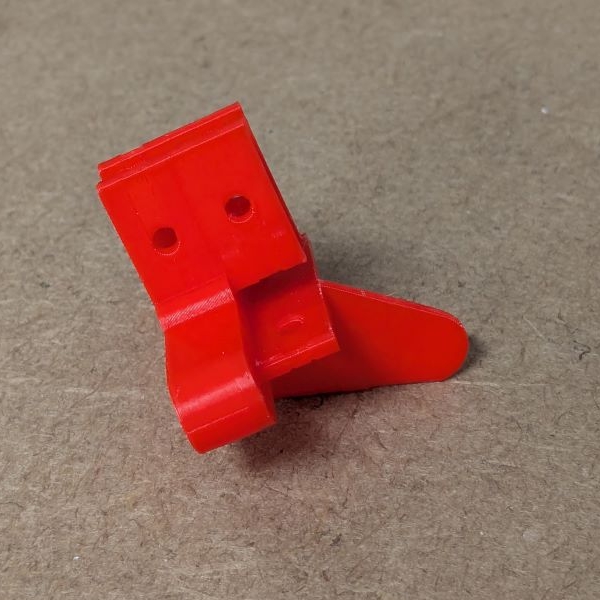

V2 - Tail mount with integrated skid fin

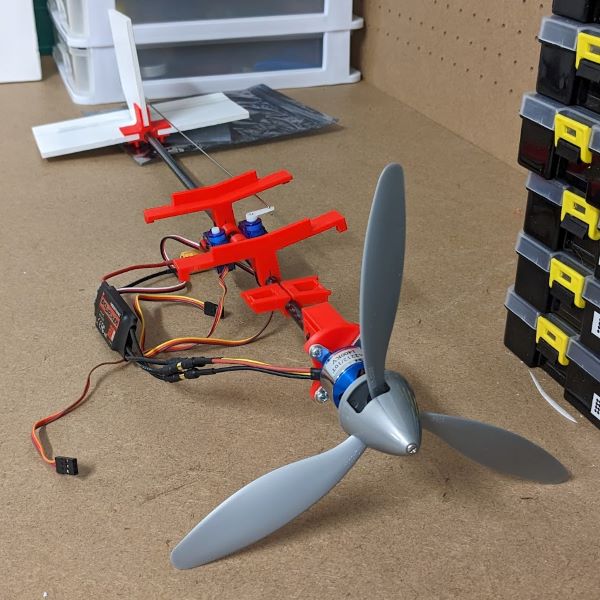

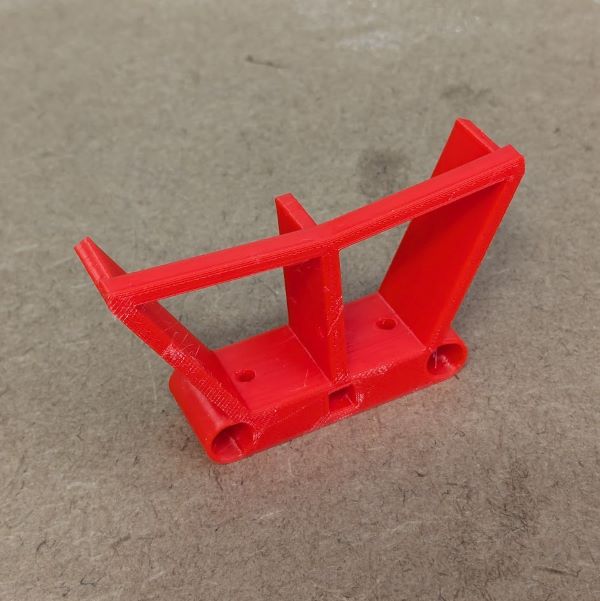

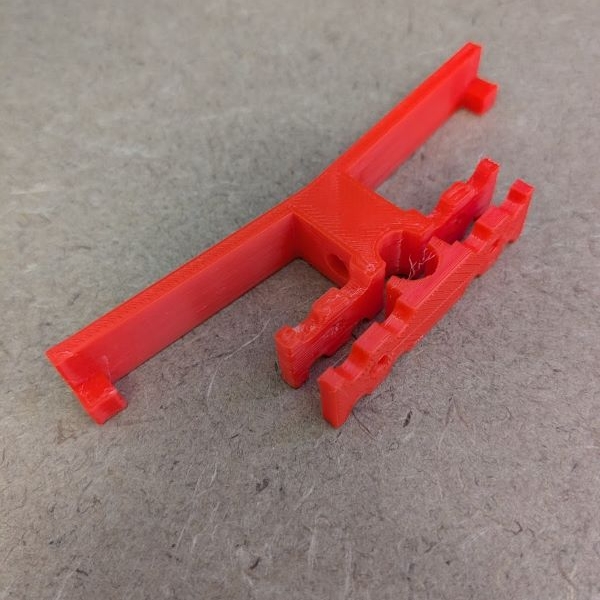

V2 - Motor mount and front wing mount fresh off the printer

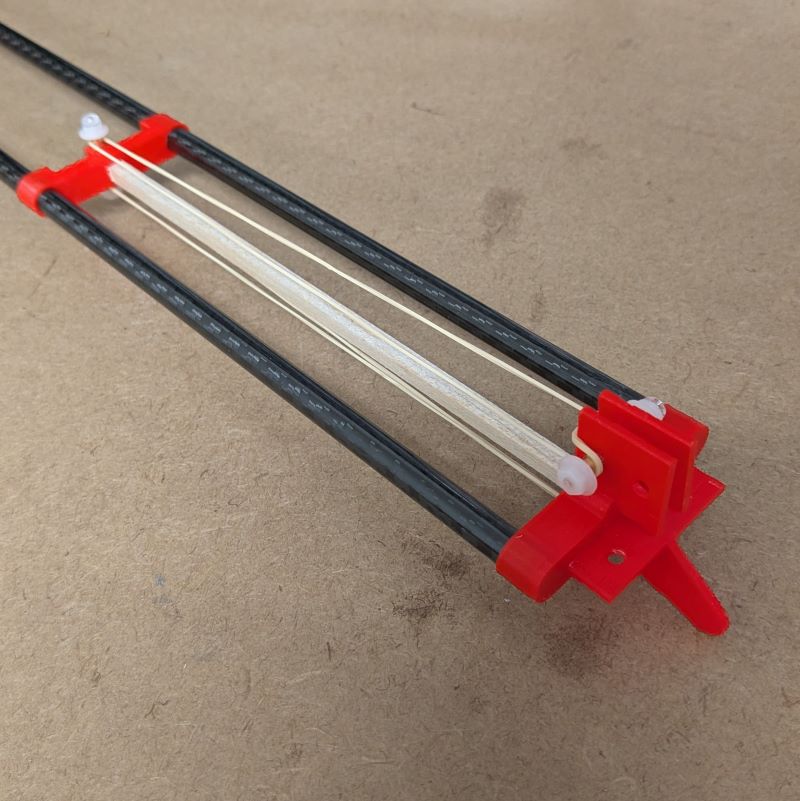

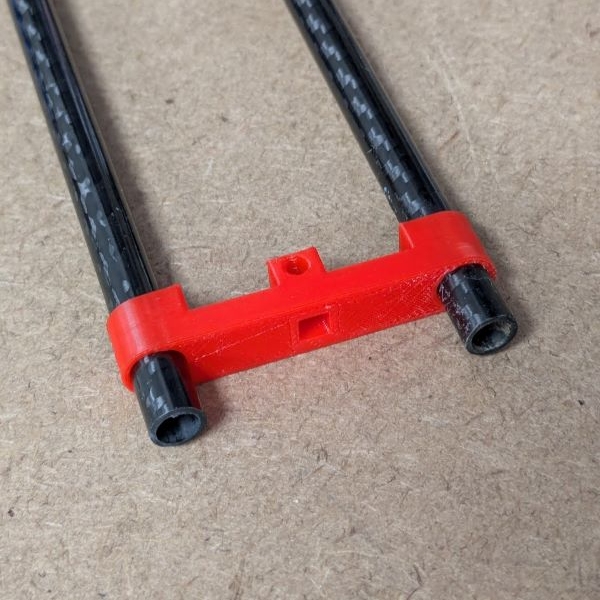

The parts will be held the right distance apart using 5mm balsa wood square rods and coupled together using rubber bands to lock them into place along the length the CF tubes. The motor and tail mounts will act as end caps.

Note the wing mount design has been simplified to improve print reliability.

Airframe redesign time

Initially my brother and I thought using a single carbon fiber tube as a stringer supporting the 3D printed "frames" would be easier and faster. However, it turned out that we were both spending almost as much time trying to get parts to stay in place (or repositioning parts after crashes) as actually flying.

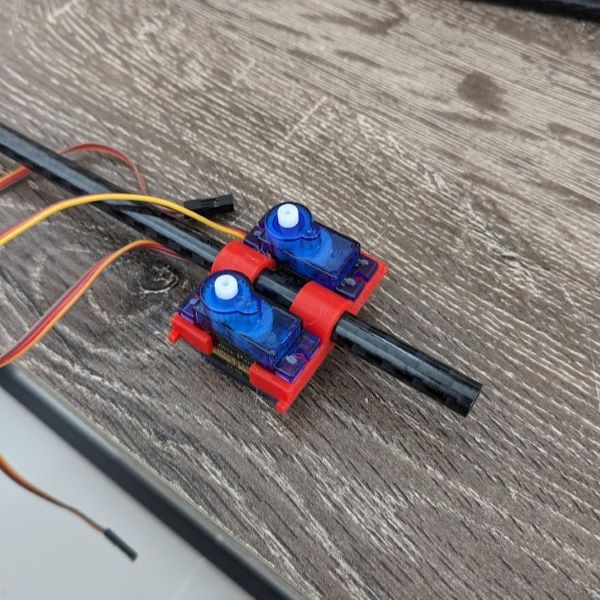

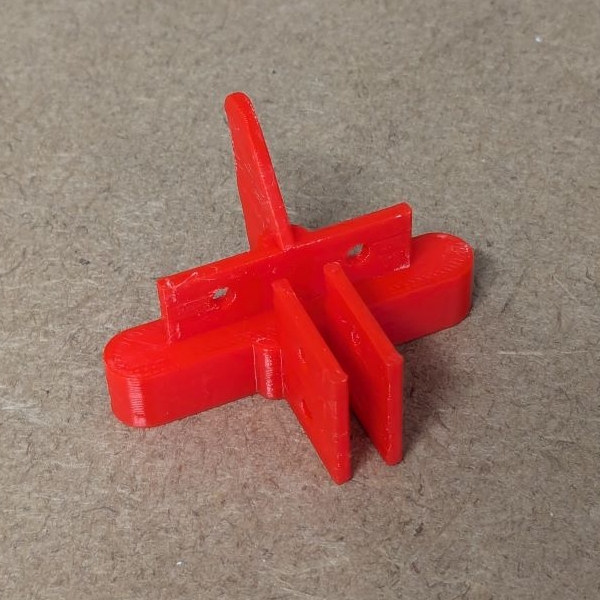

I've started designing my own dual tube version that shouldn't require any parts to be permanently attached to the tubes. The first part off the printer, half of the servo mount, is looking promising.

Powered flight testing with longer hops (and bonus crash)

Improved wing design and more powered flight testing